Find out how South West Water are using the WorkMobile non-coding toolkit to build an end-end mobile and back-office solution to manage asset maintenance and repair requests from the field enabling them to increase their first time fix rates.

Background:

South West Water (SWW) face the challenge of efficiently managing repair requests for their MEICA assets (Mechanical, Electrical, Instrumentation, Control and Automation). The existing process lacked real-time visibility, and there was a need to streamline the prioritisation of repair work. It was felt that the entire process could be improved through better business led prioritisation, information quality including the use of videos and photographs, the ability for management to quickly review, check process and authorise remedial action. This in turn would facilitate increased response rates and first-time fixes leading to a reduction in MTTR (mean-time to repair).

The Challenge:

SWW aims to empower any team member to raise repair requests seamlessly, enhancing the overall efficiency of the process. They want to eliminate ambiguity around prioritisation and ensure real-time monitoring of repair requests across their extensive asset base.

The Solution:

WorkMobile App Implementation:

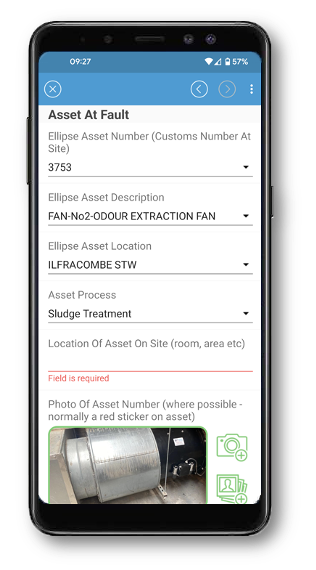

Using the form builder toolkit, business analysts at SWW built the mobile app which enables remote teams to access their entire asset list to identify the correct piece of equipment. Crucially this also supports the ability to update the asset register where information is found to be missing or incorrect such as customs numbers.

A dynamic set of questions then guides team members to record essential information including videos and photographs, and the application automatically determined the priority of each request. Auto prioritisation using business logic allows for a standardised approach to prioritisation which can then be challenged through management review/intervention in order to improve decision making around the repair of their assets. This allows SLA’s to be applied correctly ensuring an appropriate response in terms of time and resources and the criticality of the asset to process continuity.

Real-Time Monitoring with WorkMobile Portal Builder:

Business analysts at SWW used the WorkMobile Portal Builder to create of a web portal for real-time monitoring of inbound work requests.

Requests are categorised by geographical area, with dedicated monitoring teams assigned to each region.

Within the portal, requests undergo a review process, with options for authorisation, rejection, or placement on hold for additional information to ensure that decisions made are in line with business objectives allowing budgets to be approved.

Automated Assignment:

Authorised work requests are automatically assigned to either the Mechanical & Electrical team or the Instrumentation & Control team.

Results:

The implemented solution provides SWW with significant benefits:

Real-Time Visibility:

SWW have gained complete real-time visibility into the overall end to end workflow management oversight for these job types. From submission, approval, status oversight and communication to submitter, workflows and performance insights, enabling proactive monitoring and management.

Efficient Prioritisation:

Ambiguity around the prioritisation of work is eliminated, thanks to the dynamic set of questions and automated priority determination.

Streamlined Workflows:

The WorkMobile app and Portal Builder streamlines repair request workflows, making it easier for teams to report issues and for monitoring teams to manage requests effectively. Early feedback would indicate that important interventions are resulting in quicker fixes.

*workmobilesolutions provides rapid no code solutions to the Water Industry, where our platform has successfully replaced over 1,000 traditional processes—previously managed through paper, WhatsApp, email, or spreadsheets into mobile digital solutions.